What Is Seawool®? The Science Behind Oyster Shell Fabric

Color Fabric Patterns and a Variety of Species in the Background

Seawool® is a next-generation performance textile engineered through circular material science. By integrating reclaimed oyster shell minerals with recycled polymers, it bridges today’s polyester supply chains with a more resilient, lower-impact future for functional and everyday apparel.

What Is Seawool?

Wondering what is Seawool? Basically, it's a new performance textile that converts hard-to-recycle waste into useful fiber. Manufacturers collect discarded oyster shells from farms and restaurants. After that, they clean, heat, and grind them into a fine mineral powder before blending it with recycled PET bottles from post-consumer bottles. As a result, it creates chips that can be melt-spun on standard polyester lines. The Seawool fabric is actually an oyster shell fabric. That's because the shell powder is embedded inside the polymer, not coated on the surface, thanks to calcination and nano-grinding steps that lock the particles into the filament structure.

Seawool is a part of the circular textile movement since both of its key ingredients began out as trash. This trend helps materials last longer, keeps industrial waste out of landfills, and cuts down on the usage of new fossil-based polymers. At the same time, pressure to disregard short-lifecycle plastic fabrics, satisfy climate objectives, and comply with regulations is moving brands toward biomaterial-based fibers, such as Seawool, which makes a combo of recycled synthetics and natural or waste-derived ingredients. Eventually, that becomes a bridge between today's polyester-heavy supply chains and a lower-impact and bio-driven future for textiles.

How Seawool Is Made: From Oyster Shells to Functional Fiber

Full Production Process

Cleaning and Grinding Oyster Shells into Micron-Fine Powder

Shell processors receive dried shells from nearby farms and remove any residual meat, salt, and mud. So, the calcium-rich structure is all that remains. The clean shells are calcined at very high temperatures, which converts the original calcium carbonate into reactive calcium oxide with alkaline and antimicrobial behavior. After cooling, the brittle material is milled through grinding stages until it reaches a micron or even sub-micron scale. It creates uniform mineral particles that disperse in polymers and offer a huge surface area for odor adsorption and UV blocking.

Blending Shell Powder with Recycled PET

In a different stream, used PET bottles are cleaned, flaked, and turned back into recycled polyester chips. These chips may be dried and fed into an extruder like regular PET. At this stage, engineers meter in the oyster-shell-derived powder at regulated loadings. They might utilize compounding equipment and surface treatments to keep the mineral evenly dispersed and avoid agglomerates that would weaken the yarn. This is the stage where buyers asking what is Seawool discover that it is essentially a performance PET composite. Remember, the shell powder gets locked into the polymer matrix instead of just sitting as a surface finish.

Extruding into Functional Fiber

When the composite chips are done, they are spun through fine spinnerets while they are still hot. The maker may make cross-sections that are a little hollow or spiral to hold air and improve insulation. The embedded mineral phase changes the refractive index and crystallization as the filament cools. It makes the yarn feel like wool, controls odors naturally, and guards against UV rays without using chemicals. The continuous filaments are drawn, textured, and assembled into yarns that mills can knit or weave into Seawool fabric for active, outdoor, and everyday apparel.

How Taiwan's Oyster Industry Feeds the Circular Textile Loop

Taiwan's long history of oyster aquaculture on the west coast (over 160,000 metric tons of shells generated each year) implies that there is a dense cluster of farms, shell collectors, calcining plants, and textile spinners in the geography. It renders this kind of oyster shell fabric commercially feasible and scalable as a local circular solution rather than a niche R&D project. Creative Tech Textile's Oyster Odyssey research shows that 100 tons of wasted shells may make 900 tons of high-performance Seawool® and Smawarm® fiber for worldwide consumers.

Key Features and Benefits of Seawool Fabric

- Softness and Comfort Like Merino: On the body, Seawool fabric feels very close to fine Merino because the filaments are engineered with a gentle crimp and low surface roughness. Hence, they bend and don't scratch against the skin. This lets brands hit a cozy and premium hand-feel, and at the same time, use a performance synthetic blend.

- Built-In Antimicrobial Freshness, UV Shielding, and Temperature Balance

The embedded mineral phase from the shells provides natural antimicrobial properties that help control odor, scatter UV rays, and buffer temperature changes. Consequently, garments stay fresher for longer and feel more stable across hot and cool conditions. In simple terms, the yarn structure allows moisture to move away from the skin, while the mineral content adds a passive protective layer that inhibits bacterial growth. - High Performance at a Much Lower Cost: Since the fiber is produced on standard polyester spinning lines and uses industrial-scale feedstocks, the cost lands at a tenth of the quality down and a twentieth of top luxury wool. Thus, designers can build warm and functional pieces with less price pressure when scaling eco-focused collections.

- Ready for Many Different End Uses: From there, it's simple to tune yarn count, stretch, and fabric structure, and mills can supply soft knits, stable wovens, and brushed fleeces for sportswear, knitwear, uniforms, and daily basics. This flexibility also answers: what is Seawool good for in real collections, beyond being a clever oyster shell fabric story?

Comparative Analysis: Seawool vs. Common Textile Fibers

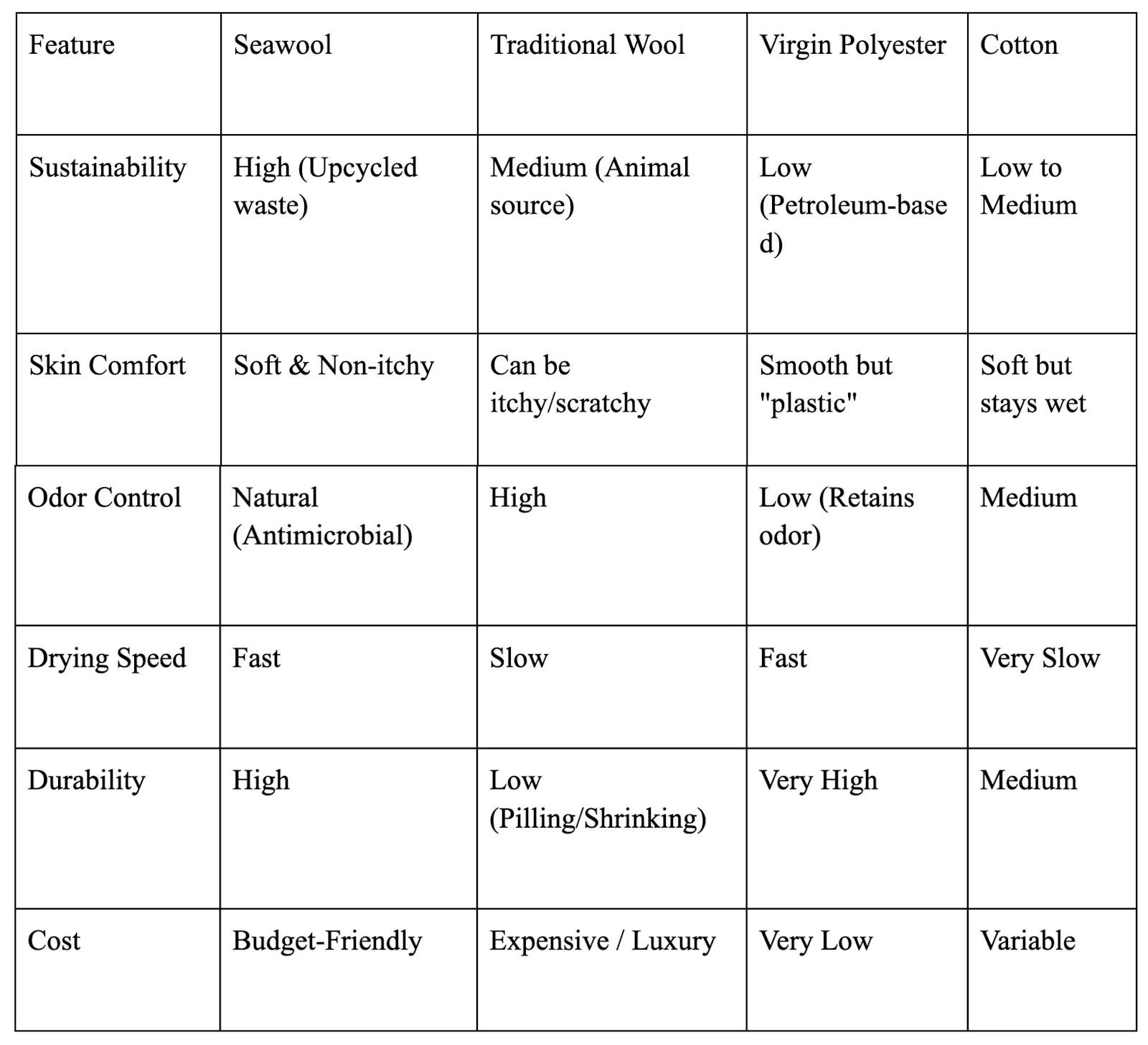

To understand the value of Seawool, it is helpful to see how it performs against traditional natural and synthetic fibers. Seawool acts as a "hybrid" material, offering the luxury feel of natural fibers with the durability of synthetics.

While Traditional Wool is prized for warmth, it is expensive and requires high-maintenance care. Virgin Polyester is durable but has a high environmental cost and tends to trap odors. Seawool bridges this gap by providing the antimicrobial and thermal properties of wool while maintaining the easy care, durability, and lower price point of recycled synthetics.

Oyster Shells Left to Rot in a Heap

Oyster Shell Fabric: Marine Waste to Global Fashion Innovation

At Creative Tech Textile, we recover spent oyster shells and marine waste and turn them into mineral powders. Subsequently, we blend those powders with recycled PET to spin our patented Seawool® fiber for global fashion and textile partners. So, this upcycling chain decreases water use by over 80% and carbon footprints at a similar scale. It is backed by ISO 14064-1 data.

Through our circular economy model and Marine Waste Alliance, brands get a traceable, Higg FEM-aligned supply chain for ESG reporting. For fashion and sportswear partners, Seawool fabric is a low-impact platform that helps collections fulfil climate targets with comfort or durability. For uniform programs, we extend the loop into eco-conscious systems that turn end-of-life garments into next-gen oyster shell fabric. Thus, each order supports ocean recovery.

Find out how Seawool and sustainable textile solutions, such as ultra-soft, eco-friendly oyster shell fabric, may change the look of your brand's next collection. To find out more, click here.

Oyster Tech Knowledge

Understanding the culture, science,

and future of oyster textiles.

In the Media

Stories in Every Shell

Every year, over 160,000 tons of oyster shells are discarded along coastlines, while the textile industry faces growing pressure to address waste and sustainability. Seawool® transforms this challenge into opportunity—upcycling oyster shells and recycled plastics (RePET) into high-performance fibers.

Through wider media coverage, we hope to spark conversations and inspire a shared vision: transforming waste into resources, for people and for the planet.

For interviews, press images, or technical background, please contact: info@creativetechtextile.com