How Sustainable Textile Companies Are Changing the Fabric Industry Globally

As regulations tighten and consumer expectations rise, sustainable textile companies are being fundamentally redefined. From circular materials and audited ESG data to traceable supply chains, this article examines how policy, technology, and transparency are reshaping the global textile industry.

The Global Shift Toward Sustainable Textile Companies

Sustainability Is Rewiring How Textiles Work

Sustainable textile companies all around the globe are redesigning the way fibers are designed, manufactured, and utilized. The ancient linear system of "take, make, waste" is being replaced with circular systems that will be more based on recycled materials, low-impact dyeing, safer chemistry, and design for disassembly. A good indicator is the Strategy on Sustainable and Circular Textiles of the Green Deal developed by the EU. It sets ecodesign rules. Thus, garments have a greater lifespan, can be repurposed and reused, and consume fewer dangerous materials throughout their life cycle. That obliges factories and brands to modernize fast.

Regulation Is Making ESG Non-Negotiable

Policy is now catching up with climate science.

- The European Green Deal is making it harder to fulfill durability, recyclability, and chemical usage standards in textiles. It may include the textile strategy, Ecodesign for Sustainable Products Regulation, and new restrictions on trash and cutting down trees.

- CSRD and SFDR demand audited ESG data on emissions, water, and social impacts.

- The Corporate Sustainability Due Diligence Directive states that brands must find and deal with risks that might be present deep in their supply chains, not only at the top level.

- Digital product passports will require product-level traceability in the EU by 2030. This means that sustainable textile companies would have to show where every fiber originates from and how it was created, not simply say it in marketing.

Consumers Now Expect Circular and Traceable Fashion

At the same time, shoppers are asking harder questions. Surveys show more than half of UK consumers think about sustainability in fashion purchases. Also, 80% of global consumers say that they may pay more for responsibly made products. People now look for repairability and resale and want proof of ethical sourcing. They also expect QR codes or online tools that show where fibers were grown, spun, dyed, and sewn. Traceability frameworks from groups like UNECE and new EU reporting rules are making that expectation a necessity. This is forcing brands to spend money on strong data and transparency systems instead of marketing slogans.

Where We Fit In: Creative Tech Textile's Role

As a materials and solutions partner, Creative Tech Textile is part of this change. We convert discarded oyster shells and marine waste into Seawool® fibers and mix them with recycled PET. We implement the same circular thinking in Smawarm® insulation and Hulk® Bio-Ceramic additives that deliver thermal regulation, bacterial control, and far-infrared benefits.

Our vertically integrated production (shell and PET collection, material processing, spinning, fabric design, dyeing, finishing, and apparel manufacturing) is managed using the Higg FEM and circular economy metrics. Thus, brands receive traceable, regulation-ready inputs rather than generic yarns. We are one of the sustainable textile companies that has been using circular systems from the beginning. Moreover, we assist our partners in turning legislation and customer pressure into real product roadmaps, not simply vague assertions about sustainability.

What Defines a Truly Sustainable Textile Company

Responsibility Starts with Real ESG, Not Slogans

Truly sustainable textile companies base their business on impact data, and not branding claims. They monitor carbon footprint, water utilization, chemistry, and waste on every level of the supply chain and connect such data to ESG goals, board oversight, and supplier scorecards. The textile and apparel sector uses 215 trillion liters of water and results in 8-10% of the carbon emissions in the world. It is among the top priority areas of ESG disclosure and governance.

That is accompanied by ethical work: living wages, safe facilities, no forced and child labor, and worker voice as part of audits and plans of improvement. The operational discipline alongside traceable supplier information earns you a system in which environmental responsibility, human rights, and governance are treated like any other important production measure.

Materials and Processes That Really Move the Needle

The next filter is what fibers and processes are employed. For instance, leaders swap conventional inputs for organic cotton, certified recycled polymers, and cellulosics. Meanwhile, they redesign dyeing and finishing to use low-liquor ratios, foam or supercritical CO₂ dyeing, and closed-loop water systems. Such kinds of shifts can cut water and energy demand in wet processing by huge margins, as well as cut toxic auxiliaries and micro-pollution.

Per Textile Exchange and recent life-cycle assessments, switching from virgin to recycled polyester can reduce greenhouse-gas emissions by 70% per kilogram of fibre. Newer low-liquor and waterless dyeing systems save 30% water and 15% energy in commercial textile lines.

For sustainable textile companies, improved feedstocks with efficient technology, heat recovery, and chemical control make a claim of green fabric real reductions in resource intensity.

Certifications That Turn Ambition into Verifiable Proof

Since claims alone are not enough, internationally recognized standards are the reference point.

- GOTS makes sure that textiles are made using certified organic fibers and conform to environmental and social standards from processing to labeling.

- GRS checks the recycled content and also checks the usage of chemicals, the management of the environment, and the social circumstances along the chain.

- OEKO-TEX® STANDARD 100 tests finished components for different harmful substances, such as heavy metals and PFAS, at limits stricter than many regulations.

- SMETA factory audits entail labor, safety, ethical, and environmental practices. They offer buyers a consistent perspective of supply chain governance and working conditions.

How We Engineer Seawool® and Smawarm® Around These Principles

At Creative Tech Textile, we design our materials platform so that it backs this hall-of-fame checklist. We convert oyster-shell waste into calcium-oxide bioceramic, refine it through nano-milling, and integrate it with recycled polymers for Seawool® fibers with low thermal conductivity, far-infrared emission, moisture management, and validated antibacterial performance. All achieves 80% lower water use and reduced carbon intensity per revenue unit.

Smawarm® builds on the same ocean-derived mineral logic. It uses hollow, air-trapping structures to reach a CLO of 3.79 at 200 GSM as an animal-free, machine-washable, fast-dry insulation with 80% lower footprint than old down systems. We provide integrated production from yarn engineering to completed garments and third-party verification using GRS, Higg FEM, and IDFL for odor control and far-infrared behavior. This is the level of architecture buyers now expect from sustainable textile companies. And it is exactly how we operate.

Innovation and Leadership in Sustainable Textile Companies

Innovation: From Linear Production to Circular Systems

Advanced sustainable textile companies are rethinking supply chains as loops instead of one-way flows. They build closed systems in such a way that offcuts, post-industrial waste, and worn garments are fed back into new yarns through mechanical and chemical recycling.

The Ellen MacArthur Foundation says that less than 1% of clothes are recycled into new ones. Every year, clothes that aren't worn or recycled lose $500 billion in value. Textile production already releases above 1.2 billion tonnes of CO₂ every year (more than international flights and maritime shipping). This is why circular business models are such a big focus for innovation.

That goes along with 3D knitting, smarter marker making, and automated cutting for decreased cutting-room waste and energy use. At the materials level, leaders are testing regenerative strategies, too, including waste-cellulose fibers that can be recycled many times to bio-based polymers for disassembly rather than landfill. For B2B buyers, this matters because it links every roll of fabric to hard data on waste, carbon, and recovery rates, not just a generic "eco" label.

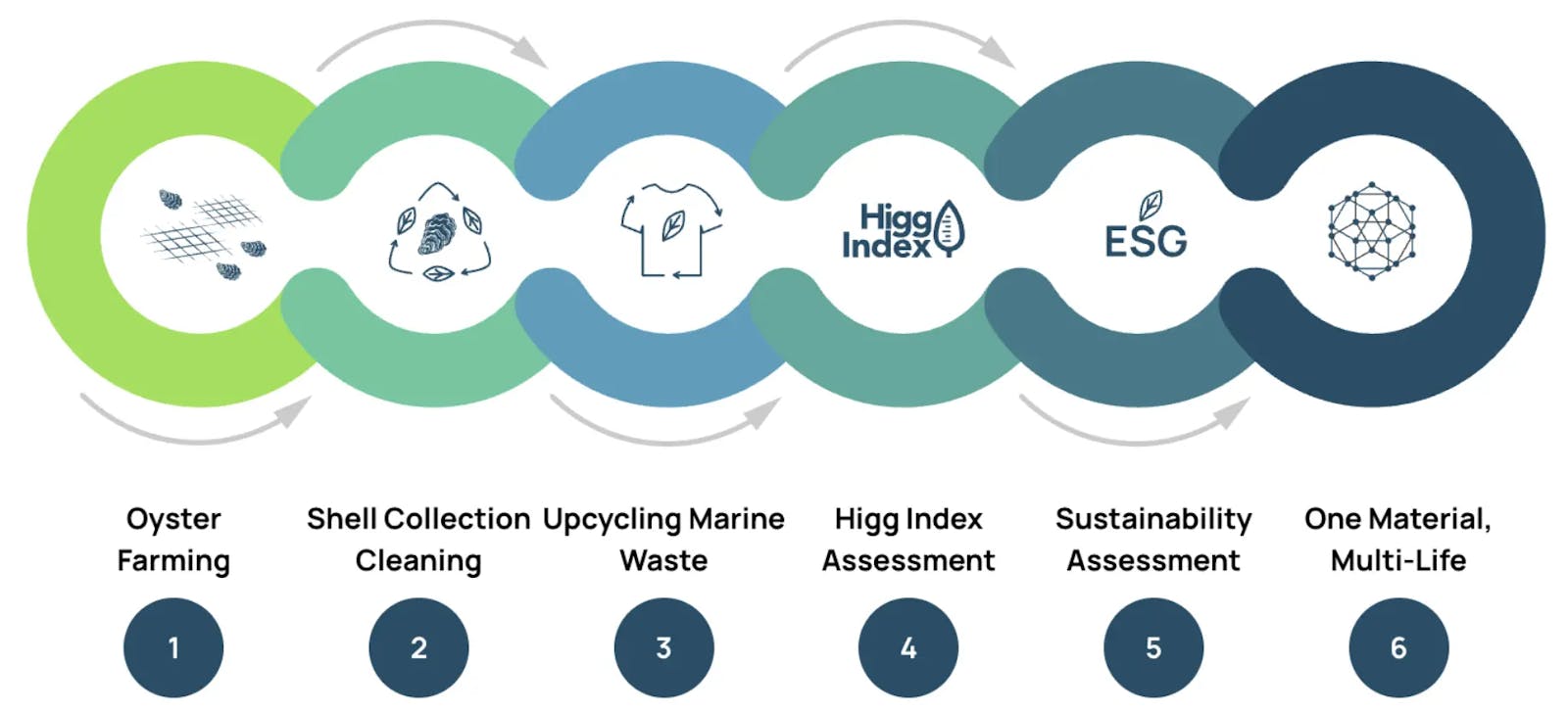

Our Role as a Circular, Brand-Ready Partner

Creative Tech Textile, an ocean-focused materials partner for fashion, uniform, and lifestyle companies, capitalizes on that trend. We run a circular chain that starts with shell collection and marine waste recovery, moves through the Higg-FEM-measured processing, and ends in multi-life material platforms that can flow into apparel, interiors, and packaging. On the ground, we co-develop fabrics with design, sourcing, and ESG teams. Then, we take them through:

- Requirements mapping.

- Lab testing and certification.

- Scaled production.

- ESG-ready reporting for line reviews and board decks.

Our Seawool® ranges are now fully commercial and are part of collections from top US apparel brands and uniform makers in Asia. We are also developing new cotton-Seawool® mixes that are perfect for mainstream lifestyle and outerwear programs in North America. Not only that, but we also work with apparel groups listed among Brand Finance's Global Top 50 and different tech-forward partners. Along these lines, every new capsule or uniform rollout can combine circular and functional materials with a story that stands up to stakeholder scrutiny.

Work with Sustainable Textile Companies for a Responsible Future

As brands race to satisfy ESG goals, map SDG impact, and move toward real circular business models, working with certified sustainable textile companies (like us) is one of the best ways to convert those goals into products that customers can touch, test, and trust. When you add Seawool® and Smawarm® to your collections, you get ocean-derived fibers that are low-carbon, water-saving, animal-free, and performance-driven. They include moisture and bacterial control alongside far-infrared warmth and high CLO ratings. All is backed by third-party data.

So, if you're ready to build a cleaner pipeline and a story for your next drop, uniform program, or capsule line, we'd love for you to check out our Ocean Smart Fiber: Seawool® and Smawarm® insulation and then get in touch so that we can help you find a solution per your exact ESG roadmap.

Oyster Tech Knowledge

Understanding the culture, science,

and future of oyster textiles.

In the Media

Stories in Every Shell

Every year, over 160,000 tons of oyster shells are discarded along coastlines, while the textile industry faces growing pressure to address waste and sustainability. Seawool® transforms this challenge into opportunity—upcycling oyster shells and recycled plastics (RePET) into high-performance fibers.

Through wider media coverage, we hope to spark conversations and inspire a shared vision: transforming waste into resources, for people and for the planet.

For interviews, press images, or technical background, please contact: info@creativetechtextile.com